Erection Inspection of Bowstring Girder: Key Parameters, Tolerances, and RDSO Compliance

- September 17, 2025

- Posted by: admin

- Categories: International, Safety

Introduction

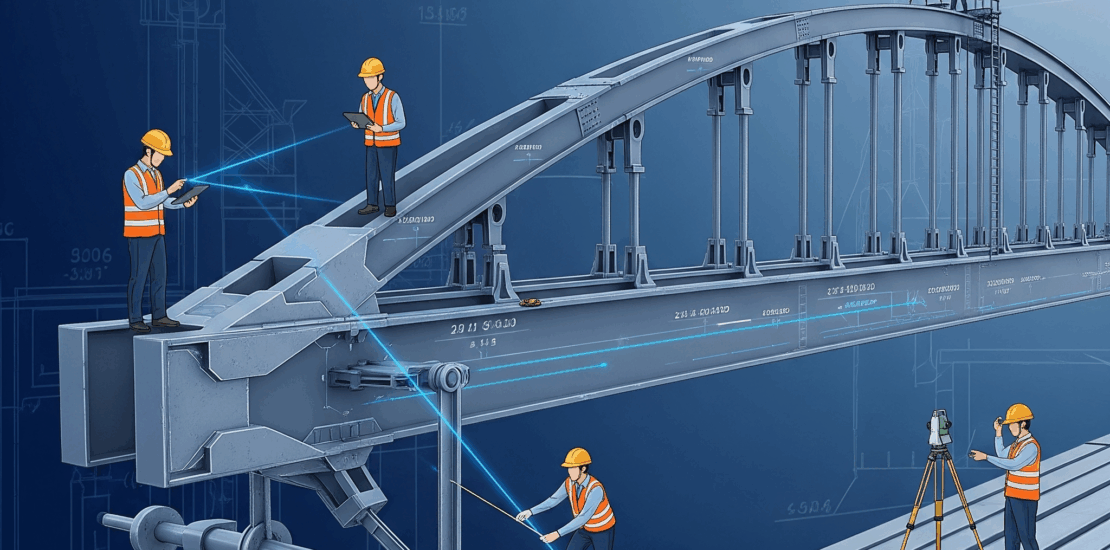

The bowstring girder is a critical structural element in bridges and railway projects. Its integrity relies heavily on precision during fabrication, transportation, and erection. Even a minor deviation in alignment or tolerance can lead to costly delays and long-term structural risks.

With the Research Designs & Standards Organisation (RDSO) recognized as a Standard-Developing Organisation (SDO) under One Nation One Standard, the bar for compliance has risen. Contractors and consultants must now adopt stricter inspection, QA/QC, and tolerance control protocols to remain competitive and compliant.

Key Parameters for Erection Inspection

1. Material and Component Verification

-

Confirm Mill Test Certificates (MTCs) for all steel sections and plates.

-

Ensure welding consumables comply with RDSO-approved specifications.

-

Verify dimensional tolerances of arch ribs, tie chords, and splice plates.

-

Review trial assembly records to ensure conformity before dispatch.

2. Alignment and Geometry Control

-

Arch Rib Alignment: Crown deviation ≤ ±5 mm.

-

Tie Chord Elevation: Tolerance within ±3 mm.

-

Verticality: Limit of 1:1000 of span length.

-

Camber Verification: Match pre-camber to counteract live load deflection.

3. Bolting and Welding Checks

-

HSFG Bolts: Torque tested with calibrated wrenches.

-

Weld Joints: Verified using UT, RT, or MPI.

-

Tack Welds: Applied as per WPS to prevent cracking.

4. Bearing and Support Inspection

-

Bearings: No gaps exceeding 0.25 mm.

-

Anchor Bolts: Confirm embedment and torque.

-

Elastomeric Pads: Check for bulging or dimensional mismatch.

5. Equipment and Safety Protocols

-

Lifting gear and cranes certified for Safe Working Load (SWL).

-

Adequate temporary bracing against wind and erection stresses.

-

Strict adherence to fall protection per IS 3696 and OSHA guidelines.

6. Post-Erection Verification

-

Deflection Monitoring: Must remain within span/1000.

-

Residual Stress Checks: Strain gauges or FEM simulation.

-

Surface Protection: Paint and coating verified with DFT gauges.

-

Final Survey Certification: Total station survey confirming geometry.

RDSO Tolerances and Compliance

RDSO mandates tolerances for consistency and safety:

-

Hole Diameter: +0.3 / –0.0 mm.

-

Hole Spacing: ±1 mm up to 1 m, ±2 mm beyond.

-

Weld Thickness: –1.0 / +0.0 mm.

-

Camber Deviation: ±5 mm.

-

Verticality: Max deviation 1 in 1000.

Non-conformities must be documented, corrected, and approved before proceeding—underscoring the importance of rigorous inspection regimes.

Lessons from Field Failures

A forensic case in India highlighted that arch rib misalignment and poor welding led to localized buckling of a bowstring girder. The outcome: a three-month project delay and heavy financial penalties.

👉 The takeaway: early-stage QA/QC, calibrated survey tools, and adherence to RDSO tolerances are non-negotiable safeguards.

Role of Digital Tools in QA/QC

Modern inspection increasingly relies on digital solutions:

-

BIM Models – simulate erection sequences and detect clashes.

-

Laser Scanning – real-time geometry verification.

-

NDT Automation – faster weld testing with higher accuracy.

-

Digital Dashboards – track inspection data, NCRs, and approvals in real time.

These tools not only enhance compliance but also streamline audits under RDSO and ISO frameworks.

NexFore Consulting’s Expertise

NexFore Consulting offers tailored solutions for bowstring girder projects:

-

RDSO-compliant inspection checklists.

-

QA/QC audits across fabrication and erection phases.

-

Training for site engineers on tolerances, NDT, and safety.

-

Deployment of ISO 9001/45001 frameworks with digital dashboards.

Our philosophy: compliance is not an obligation—it is a strategic advantage that boosts reliability, client trust, and profitability.

Conclusion

Bowstring girder erection is a precision-driven process, where millimeter deviations can compromise safety and performance. With RDSO’s elevated authority as an SDO, adherence to tolerances, QA/QC protocols, and inspection checklists is essential for competitive participation in India’s infrastructure projects.

Firms that embrace digital tools, system-oriented compliance, and workforce training will emerge as leaders in quality and safety.

Compliance is no longer optional—it is the foundation of competitiveness.

Contact us at the Consulting WP office nearest to you or submit a business inquiry online.

FAQs

Q1. Why is erection inspection of bowstring girders critical?

Bowstring girders are complex structural elements. Even a deviation of a few millimeters in arch alignment, tie chord elevation, or welding thickness can compromise stability. Erection inspection ensures geometry, tolerances, and load paths are compliant with design and RDSO standards.

Q2. What are the most important parameters to check during erection?

Critical parameters include material verification (MTCs, welding consumables), arch rib alignment, tie chord levels, bearing seating, bolt torque, welding quality, and post-erection deflection checks. These collectively ensure structural integrity.

Q3. What tolerances are mandated by RDSO for bowstring girders?

RDSO typically mandates:

-

Hole diameters: +0.3/–0.0 mm

-

Hole spacing: ±1 mm (up to 1 m), ±2 mm (beyond 1 m)

-

Weld thickness: –1.0/+0.0 mm

-

Camber deviation: ±5 mm

-

Arch verticality: ≤ 1:1000 span length

These tolerances ensure interchangeability and safety.

Q4. How can contractors ensure compliance during erection?

Contractors must:

-

Use calibrated instruments (total stations, torque wrenches).

-

Document all inspections.

-

Apply NDT for welding checks.

-

Adopt digital dashboards for QA/QC traceability.

-

Train staff in RDSO and ISO requirements.

Q5. What role does technology play in modern erection inspection?

Tools like BIM models, laser scanning, and digital dashboards allow real-time geometry validation, faster error detection, and transparent audit trails. These reduce delays and strengthen compliance documentation.

Q6. How does NexFore Consulting support girder erection compliance?

NexFore offers RDSO-compliant inspection checklists, QA/QC audits, site engineer training, and ISO-integrated digital dashboards. This ensures clients not only comply but also gain competitive advantage by delivering safer, faster, and more reliable projects.