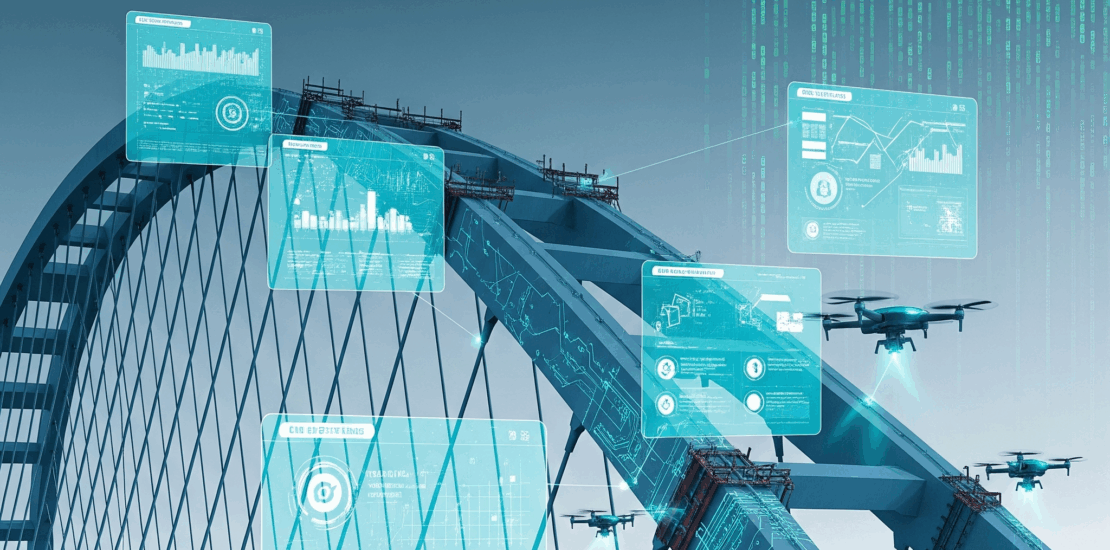

Innovations & Best Practices in QA/QC for Bowstring Girder Erection Using Digital Tools and Predictive Analytics

- September 17, 2025

- Posted by: admin

- Categories: International, Safety

Introduction

The erection of bowstring girders—those elegant arch-and-tie structures integral to bridges and rail infrastructure—demands extreme precision. Traditional QA/QC methods, while valuable, often fall short when confronted with today’s ambitious timelines, stringent RDSO tolerances, and heightened safety expectations.

The future lies in digital tools and predictive analytics. By combining BIM, laser scanning, IoT monitoring, and AI-driven models, companies can move from reactive inspections to predictive quality control—ensuring safety, compliance, and competitiveness.

Why Traditional QA/QC is No Longer Enough

Manual measurement and paperwork-based QA/QC present challenges:

-

Errors in alignment undetected until late stages.

-

Weld defects only found after critical connections.

-

Limited traceability for audits and approvals.

-

Reactive correction—delays, rework, and cost overruns.

With RDSO standards becoming more rigorous, the industry must transition to tech-driven inspection regimes.

Digital Innovations in Bowstring Girder QA/QC

1. Building Information Modelling (BIM) & Digital Twins

-

BIM models simulate erection sequences, load transfers, and clash detection.

-

Digital twins update in real time, reflecting actual site conditions.

-

Enables early detection of risks like camber deviations or joint fitment issues.

Best Practice: Incorporate BIM into QA/QC planning from tender stage.

2. Laser Scanning & Photogrammetry

-

Laser scanners create 3D point clouds of girders with ±2 mm accuracy.

-

Detects arch misalignment or tie chord elevation errors instantly.

-

Drones with photogrammetry provide aerial validation on large spans.

Best Practice: Validate geometry after each stage—bearing installation, arch lift, and tie chord connection.

3. IoT Sensors & Live Monitoring

-

Torque sensors confirm HSFG bolts meet tightening specs.

-

Strain gauges detect abnormal stress during lifting.

-

Real-time dashboards provide alerts when parameters breach RDSO limits.

Best Practice: Use IoT-based monitoring as part of erection QA/QC checklists.

4. Automated Non-Destructive Testing (NDT)

-

Automated ultrasonic testing (AUT) and radiography drones ensure weld soundness.

-

AI-assisted defect detection reduces inspector subjectivity.

-

Records stored digitally for audit traceability.

Best Practice: Standardize automated NDT for critical welds in arches and tie chords.

5. Digital QA/QC Dashboards

-

Centralizes inspection data, NCRs, and approvals.

-

Integrated with ISO 9001/45001 frameworks.

-

Provides real-time transparency to clients and auditors.

Best Practice: Make dashboards mandatory for QA/QC reporting.

Predictive Analytics: The Game-Changer

While digital tools validate current quality, predictive analytics forecasts risks before they occur:

-

Deflection Prediction: Models simulate expected girder deflections under self-weight.

-

Weld Risk Assessment: AI predicts defect probability using humidity, batch data, and welder history.

-

Erection Sequencing Optimization: Machine learning suggests sequences with minimal residual stress.

-

Fatigue Forecasting: Predicts lifecycle risks, enabling preventive reinforcements.

Best Practice: Build predictive libraries from historical project data for continuous improvement.

RDSO Compliance in a Digital Framework

RDSO tolerances—such as hole spacing ±1–2 mm, camber deviation ±5 mm, and verticality ≤ 1:1000—are strict. Digital QA/QC ensures:

-

Automated comparison of scans with RDSO benchmarks.

-

Immediate alerts for out-of-spec dimensions.

-

Digital evidence trail for audit readiness.

Result: Compliance becomes measurable, provable, and faster to approve.

Case Example: Digital QA/QC in Action

In a metro viaduct project, engineers used BIM, laser scanning, and IoT torque sensors during bowstring girder erection. When minor elevation deviations appeared, the system issued real-time alerts—allowing corrections before final welding.

Outcomes included:

-

Zero NCRs.

-

20% reduction in inspection cycle time.

-

Faster RDSO audit clearance.

NexFore Consulting’s Innovation Advantage

At NexFore Consulting, we help infrastructure leaders adopt digital QA/QC and predictive analytics for bowstring girder erection. Our services include:

-

Designing RDSO-compliant digital QA frameworks.

-

Deploying laser scanning, BIM integration, and IoT monitoring.

-

Training teams on AI-driven inspection methods.

-

Building predictive models from client project data.

We ensure QA/QC shifts from a compliance burden to a business differentiator.

Conclusion

Erecting bowstring girders with accuracy is a structural necessity—but in today’s infrastructure landscape, it’s also a strategic advantage. By adopting digital QA/QC tools and predictive analytics, companies can move beyond compliance to deliver faster, safer, and more reliable projects.

With RDSO’s elevated standards, the future belongs to firms that see compliance not as a cost—but as a competitive edge.

At NexFore Consulting, we stand ready to guide you into that future.

Contact us at the Consulting WP office nearest to you or submit a business inquiry online.

FAQs

Q1. Why are digital tools essential in bowstring girder QA/QC?

Digital tools such as BIM, laser scanning, and IoT sensors provide real-time data with millimeter accuracy, reducing human error and enabling faster detection of misalignments, weld defects, or torque issues. This enhances compliance with RDSO standards and saves both time and cost.

Q2. How does predictive analytics improve erection inspection?

Predictive analytics uses historical and live data to forecast risks like excessive deflections, weld failures, or stress concentration. By simulating erection sequences and load responses, it helps contractors prevent errors before they occur—transforming QA/QC from reactive to proactive.

Q3. What are the best practices for implementing BIM in QA/QC?

Integrating BIM early in the project lifecycle ensures clash detection, geometry visualization, and sequencing are digitally planned. Linking BIM to QA/QC dashboards allows direct comparison between “as-built” scans and design models, ensuring compliance at each stage of girder erection.

Q4. How does RDSO compliance benefit from digital QA/QC?

Digital QA/QC provides traceable, tamper-proof records of inspections, weld tests, and geometry checks. Automated comparisons against RDSO tolerances generate instant compliance evidence, reducing disputes and accelerating approval cycles.

Q5. Can IoT and sensors replace human inspectors?

No. IoT sensors and digital tools augment but do not replace human expertise. They provide accurate, continuous monitoring—such as bolt torque, strain, and vibration data—that empowers inspectors to make better, faster decisions. The synergy of human judgment and machine precision is the best practice.

Q6. How can NexFore Consulting help organizations adopt these innovations?

NexFore supports clients with RDSO-aligned digital frameworks, BIM and IoT integration, automated NDT processes, and predictive QA/QC models. We also train teams to apply these innovations effectively, making compliance a competitive advantage.